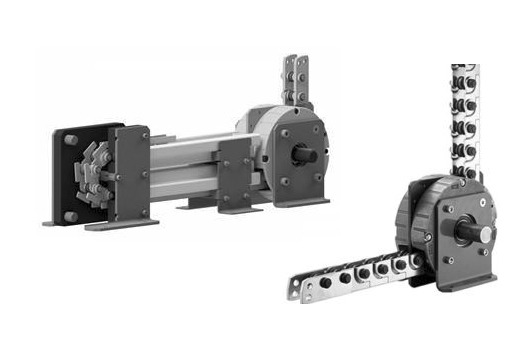

How Does a Linear Chain Work?

Designed for applications with space limitations, the Linear Chain from GROB GmbH Antriebstechnik can operate in both directions—it can pull and “push”. The chain is made of specially formed links, whose geometry prevents the chain from buckling under heavy loads. Due to both the design of the drive housing and to the special profile of the chain links with its interlocking fingers, the Linear Chain can be rolled up efficiently into a small storage area, unlike traditional linear drives where significant installation space is needed for the spindle stroke.

How the Chain “Pushes”

Through the drive element, typically an electric motor, thrust force is applied to the chain links. The shoulders of the individual chain links then press against each other, forming a rigid unit. This allows them to lift or push the load. Thus, the chain becomes a rod that surpasses the cylinder in terms of range, load capacity, speed, and precision. Additionally, the Linear Chain can be practically “infinitely” long, while a lift cylinder cannot simply be extended.

How the Chain “Pulls”

In the other direction, when pulling, it functions like a regular chain. However, the unloaded part of the Linear Chain is only half as long and doesn’t need to be stored parallel to the travel path. Instead, it can be redirected to a location with sufficient space. The Linear Chain can be rolled up like a rope. The main advantage is that the Linear Chain can be coiled and stored where space is available.

How the Drive Works

The chain is driven by a chain wheel located in the drive housing. The drive housing not only handles the driving and guiding of the chain but also redirects the chain by 90° or 180°. As a result, the space behind the drive housing is never occupied by the chain. The housing is additionally equipped with a drive shaft, which can be configured on side A, side B, or both sides. This drive shaft allows for the attachment of a geared motor.

To store the chain, a custom storage solution in steel profiles can be provided by the customer. Alternatively, chain magazines, chain covers, or guide rails can be used to handle the task of chain storage.

Where is the Chain Used?

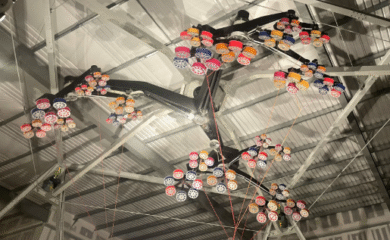

Typically, the Linear Chain can be used for tool or material handling applications, warehouse logistics, as well as conveyor systems or rolling mills and steel works. With heat-resistant versions available, capable of operating continuously at 560°C, the Linear Chain can be used in industrial furnaces. The Linear Chain also works well at low temperatures and is available in stainless steel, making it suitable for use in cooling systems in the food industry. Other common applications include moving heavy loads in automotive manufacturing, for stage platforms in theatres or for scissor lifts.

Advantages

The Linear Chain offers stroke speeds up to 250 mm/s; in special cases speeds of up to 1,000 mm/s are possible. The push-pull actuator also offers low-cost operation and easy maintenance, as worn parts or chain links can be quickly and easily replaced without the need to modify the entire system. For higher load carrying requirements, GROB GmbH Antriebstechnik also offers the Tower Chain. An advancement on the design of the Linear Chain, the Tower Chain’s geometry allows higher strokes and forces without guidance.