NO WEAK LINKS WITH LINEARCHAIN TECHNOLOGY

The Grob Linear Chain is a special product in linear drive technology as it functions just like a bar, with the capability to both pull and push. What seems like a contradiction at first glance is, on closer inspection, an ingenious solution in linear drive technology – and it is available in the UK from R.A. Rodriguez (U.K.) Limited.

A simple concept, Linear Chain leads to an endless number of possibilities over other drive solutions such as traditional chains, which can only pull, and cylinders, which unlike LinearChain need to retract a distance equivalent to their length. A combination of cylinder and chain without the disadvantages mentioned would be ideal, hence the development of Linear Chain.

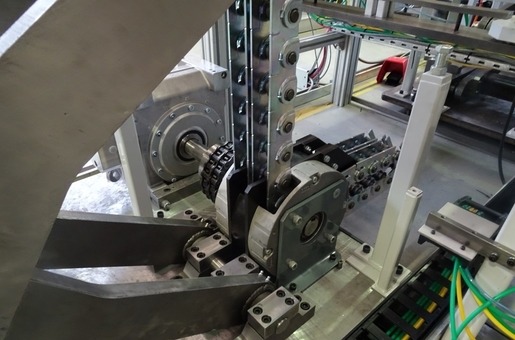

The product consists of specially formed, high-precision mechanical chain links that engage positively with one another to provide mutual strength and support (as a rigid unit), thus facilitating both pull and push capability. Importantly, Linear Chain is a purely mechanical movement actuator and is thus environmentally friendly, reliable and requires little maintenance. Stroke lengths of up to 30m are easily achievable.

With more and more machine builders and system integrators becoming aware of the benefits on offer, R.A. Rodriguez is able to cite a myriad of successful Linear Chain applications.

A frequently requested task for Linear Chain is lifting. Applications such as table and platform lifts benefit from the space-saving and easy positioning attributes of the product. Stroke force of up to 35kN is possible with one chain, a factor that also makes this solution suitable for further types of lifting system, including scissor lifts and lifting columns. Often, a single motor is sufficient to drive two parallel Linear Chains.

A recent customer project saw a Linear Chain installed in a lifting column with a length of 6m for the safe transportation of heavy loads between building floors. Two directional changes of the Linear Chain through 90° enable parallel storage of the chain in the system. Consequently, installation engineers could either mount the lifting column directly as a free-standing unit on the floor, or with additional fastenings to the ceiling or wall without requiring further space for chain storage. Ultimately, Linear Chain ensures the lifting column can position large loads precisely within constricted space conditions.

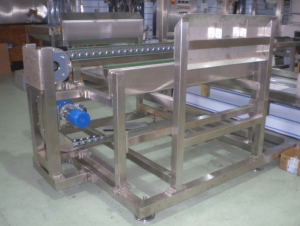

Of course, systems that require horizontal motion can also gain from the adoption of Linear Chain. A case in point is the provision of infeed and outfeed motion to an industrial washing machine for pharmaceutical transit boxes.

In another example, Linear Chain is aiding the transfer of shipping containers from rail to road transport, and vice versa. This operation takes place in a time of less than 3 minutes without the need for a crane or forklift.

Further recent applications include the forwarding of workpiece loads in and out of a heat-treatment furnace, and the use of Linear Chains (attached to a plunger) for pressing raw tobacco into transport containers. The latter takes place at a stroke speed of 300mm/s.

Linear Chain is also finding favour at a number of automotive OEMs, with one plant using the product for an engine marriage system. This system features two tables, each of which lifts and lowers using a Linear Chain with 35kN lifting force and 2m stroke length. The first table lifts and engages its pallet with a front-end engine assembly from the plant’s monorail system, before the table lowers and the engine transfers to the second table via a conveyor. Subsequently, the second table raises up from where two line workers guide the engine into the car and secure it in place using nut-runners. While this is taking place, the empty pallet returns to the first table via a second conveyor.

Another advantage of the Linear Chain is that it is able to operate in extremes of temperature, both low and high. This video demonstrates how you can streamline the process of freezing large quantities of fresh foods. Here, Milmeq, the specialists in automated chilling and freezing systems for food processing operations have incorporated the Grob Linear Chain to slide the boxed food forward into the freezer compartments.

Thanks to high positioning accuracy, constant stroke speed and shock-free motion with no elastic hysteresis under load, the potential uses for Linear Chain are virtually endless. Some of the more unusual projects to date have involved the movement of flower boxes in commercial greenhouses, and lifting equipment in theatres. The only limit on application, it appears, is imagination.